Every grain count's

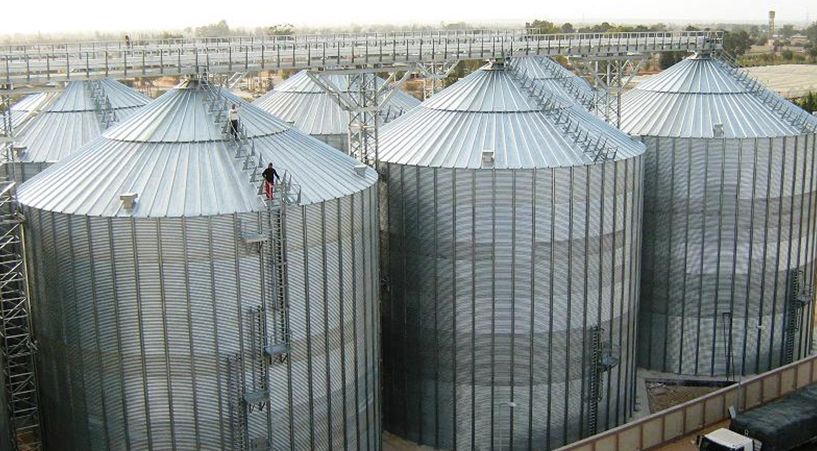

TSP is committed in providing world class post-harvest management solutions in grain storage and grain management. Our motto, "Every grain count's" emphasis how important it is for us to consider each grain as a living organism.

Every storage solution starts with the right advice

Storage decisions can affect your operation for decades. That's why so many companies around the world trust TecSpec with their storage needs. Not only do we support some of the most advanced storage products available, but we also support our products with the expert project leadership and sound engineering advice necessary to ensure that the decisions you make today continue to serve your company well for years to come.

Every storage solution starts with the right advice

Material Handling

- 1. High Speed Grain Bucket Elevators

TSP – Farm range – 5TPH to 150TPH

TSP – Commercial range – 150TPH to 1200TPH

- Height up to – 45 meters, Capacity up to 1200TPH

- Centrifugal discharge – High speed

- Twin leg or single leg

- Explosion protection system

Aspiration Nozzle:

Installed on the bucket elevator pipes for dust removal of internal surfaces (Optional).

Sealing:

Parts joints are sealed to prevent grain dust emission outside the bucket elevator/

Belt:

Wide range of belts oil resistant, wear-resistant, antistatic, with protection against ignition and hot oil, etc. The belt joint is released with overlap, stitching through buckets.

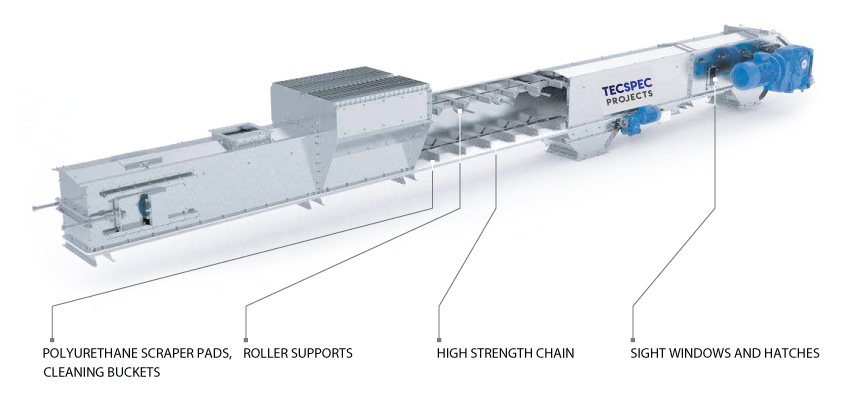

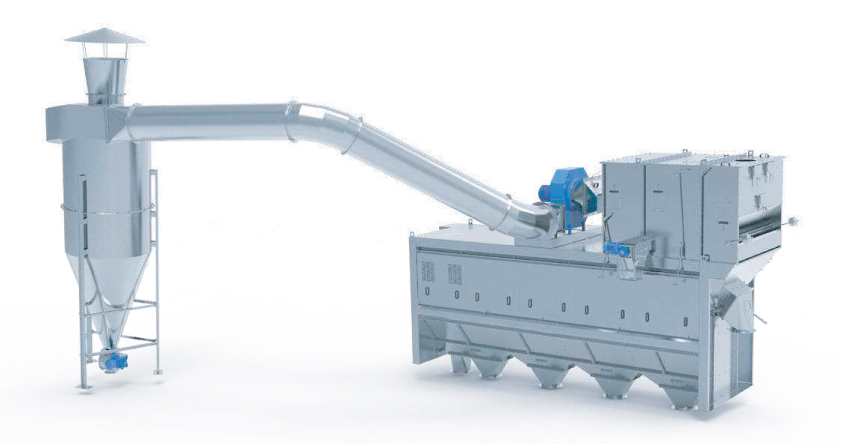

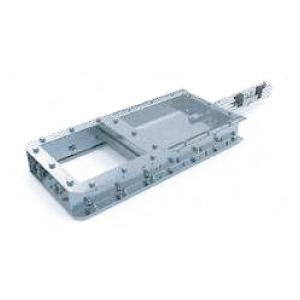

- 2. Chain Conveyors

Length up to – 70 meters – single conveyor, capacity 5 TPH - 800TPH

Protecting lining:

We offer chain conveyors - with lining and without lining.

Chain conveyors are lined to increase their service life by eliminating the wearing of their structures. The protected parts typically include the bottom and, if necessary, side walls to the conveyed product level. The lining sheet material is bolted.

Bearing units:

Exterior placement of bearings simplifies maintenance and protects the grain mass from ignition when unlubricated bearings are heated. Flanged bearing units.

Unloading section and sliding gate:

Unloading hopper and baffle plate prevent the product from contacting the drive sprocket. Intermediate longitudinal sliding gate with a special design eliminates grain penetration and uneven wear of the scrapers.

Double-pitched roof:

Prevents stagnation of water on the conveyor roof. Seals the conveyor tightly, prevents moisture and pests from getting inside, and grain dust outside.

Geared motor:

Geared motors with motor protection class not less than IP54 ensure stable performance. Start-up is possible when the conveyor is fully loaded with grain. Geared motors are mounted on the hollow shaft of the drive station.

GRAIN DRYERS

High-efficient grain dryers which runs on alternative fuel (wood chips),

diesel or LPG.

Scalability:

Wide product range. Production capacity from 9 to 300 t/h.

Automation – Minimization of error:

- Grain dryer with 100% automation. Process control from the operator’s workstation.

- Temperature monitoring.

Versatility:

- Drying of all types of cereal crops, oilseeds, and legumes.

- High efficiency in wet grain handling.

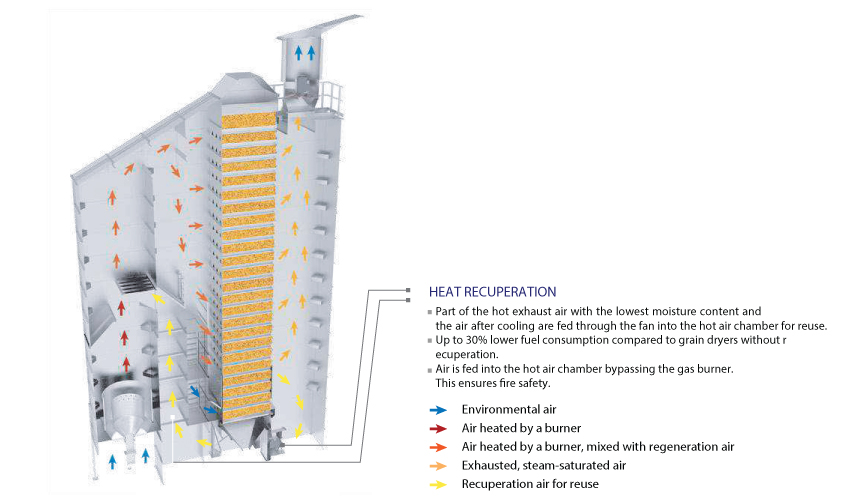

Saving of operating cost:

Recuperation

Environmental safety and quality:

Aspiration system that captures up to 97.85% of dust.265wei

Line Accessories

We produce a wide range of auxiliary equipment for grain logistics at the elevator complex

GRAVITY FLOW EQUIPMENT

For moving the product.

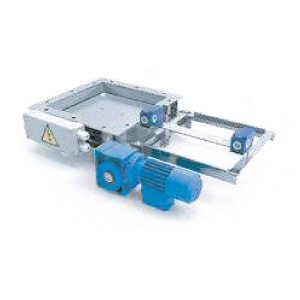

RACK AND PINION GATES

For controlling the grain flow.

PNEUMATICALLY OPERATED GATE VALVES

For interrupting the grain flow.

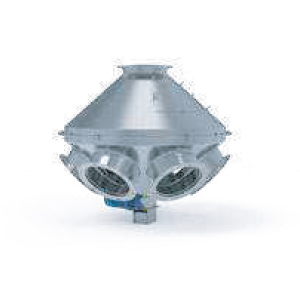

REVERSING VALVES

For changing the direction of product movement.

- Equipment throughput: up to 1.500 t/h.

- Lined with wear-resistant materials.

MECHANIZED GRAIN FLOW DISTRIBUTOR

For changing the direction of product movement.

GRAIN Management

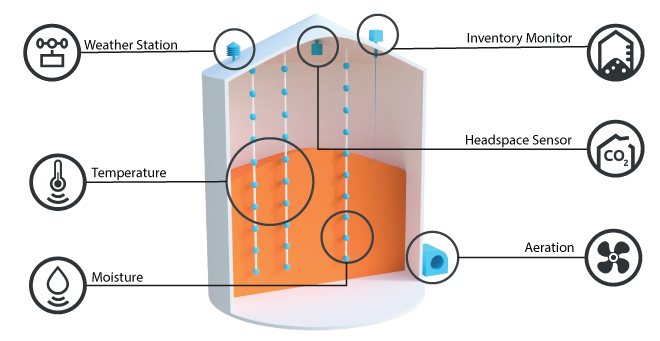

Why do we need grain monitoring system?

- Grain is the most import source of human food and animal feed

- Shortage of grain due to overgrowth in population

- Increasing prices

- Up to one third of global production of grain harvested is lost

- High grain moisture and heat are still the greatest risk during storage

- High grain quality is a key factor to improve profitability

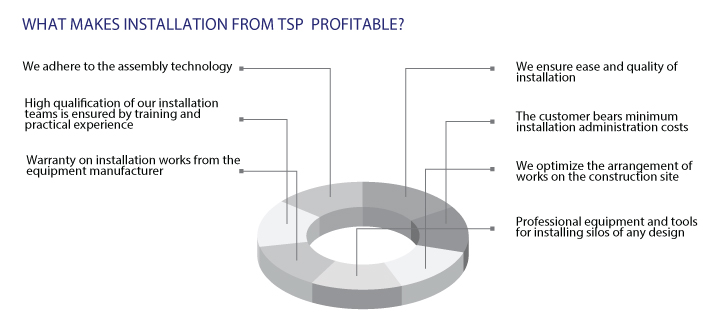

EPC and Engineering

Correct installation is the key to quality and trouble-free operation of the equipment throughout the entire period of operation.

Most problems occur due to poor installation, especially when the silo is fully loaded rather than during commissioning. Undedicated third-party teams lack knowledge and skills in assembling grain storage equipment, as opposed to the TSP installation teams.

- We carry out works on installation of the elevator complex equipment, automation, equipment setup and commissioning.

- We carry out professional inspection, diagnostics, and repair of equipment.

- We train elevator complex personnel.

- We install both our own elevator complex equipment and equipment from other manufactures.

- The company’s capabilities allow for simultaneous installation of several objects.

- The customers who order the equipment installation from TSP receive an extended warranty on our equipment.